Environment Partners

AMETEK Land Instruments | Fives | Neo Monitors | RJM International | Scentroid | TCR Tecora | UniTec

Under this division, we supply, install and commission all kinds of environmental monitoring devices, be it Ambient Air quality monitoring, stack monitoring, moving vehicles monitoring, fence line monitoring, etc., We are also capable of auditing of CEM systems by using USEPA methods. We do have approved quality instruments, Mobile Laboratory and trained & certified staff to carry out the works.

AMETEK Land Instruments

AMETEK Land is a specialist in the design and manufacture of monitors and analysers for industrial infrared non-contact temperature measurement, combustion efficiency and environmental pollutant emissions.

Combustion Efficiency Monitors

Combustion Efficiency MonitorsClose monitoring of oxygen, carbon monoxide and sulphuric acid dewpoint can help improve combustion efficiency, lower energy use, reduce emissions and prevent plant corrosion. We offer precision measurements for these applications.

FGA Series

A compact, reliable multi-gas analyser for measuring flue gas emissions in processes burning natural gas and biomass.

WDG 1200 & 1210 (Oxygen)

A highly flexible range of high-precision flue gas oxygen analysers developed specifically for combustion analysis and control applications.

Lancom 200 (Sulphuric Acid Dewpoint)

A portable monitoring device using conductive cell technology for accurate, periodic measurements of the Acid Dewpoint Temperature (ADT) in combustion processes.

Portable Gas Analysers

The Lancom 4 range lets you take AMETEK Land’s cutting-edge, easy-to-use gas analysis on the move. With up to nine gas measurements on a single analyser, there are solutions for combustion monitoring and environmental compliance.

Lancom 4

Compact portable multigas analyser, capable of measuring up to eight flue gases in a range of combustion and emissions processes.

Opacity and Dust Monitors

The most advanced range of opacity, dust and particulates monitors available, use patented technology to deliver highly accurate results. With no moving parts, they combine high reliability with low maintenance.

4500 MkIII (Opacity – US EPA PS-1 & ASTM D6216)

A high-specification opacity and dust monitor meeting US and European standards for monitoring combustion processes.

4750-PM (PM-CEMS – EN 15267)

A back-scatter laser PM analyser designed for use as a continuous emissions monitor for compliance or process monitoring.

4650-PM (PM-CEMS – QAL1)

High-sensitivity, forward-scatter laser measurement for particulate matter, for use in combustion processes where condensed water is not present.

4400 (Opacity – EN 15267)

Dust and opacity monitor for monitoring combustion processes where automatic calibration checks are not needed

Carbon Monoxide Detectors

Providing early warning of combustion in process and storage areas, our highly sensitive CO detectors monitor the entire process. This gives the best chance of early detection, allowing rapid action to prevent fire.

Millwatch

An advanced carbon monoxide detector designed to provide early warning of spontaneous combustion in pulverisers for coal and biomass.

Silowatch

An advanced carbon monoxide detector designed to provide early warning of spontaneous combustion in coal and biomass storage silos.

Fives

Flame monitoring for all industrial burners

Fives designs and supplies machines, process equipment and production lines for the world’s largest industrials including the aluminium, steel, glass, automotive, aerospace , logistics, cement and minerals, energy and sugar sectors.

Located in nearly 30 countries and with nearly 8,700 employees, Fives is known for its technological expertise and competence in executing international projects.

Fives’ multi-sector expertise gives it a global vision of the industry which provides a continuous source of innovation. The effectiveness of its R&D programs enables Fives to design forward-thinking industrial solutions that anticipate clients’ needs in terms of profitability, performance, safety and compliance with environmental standards.

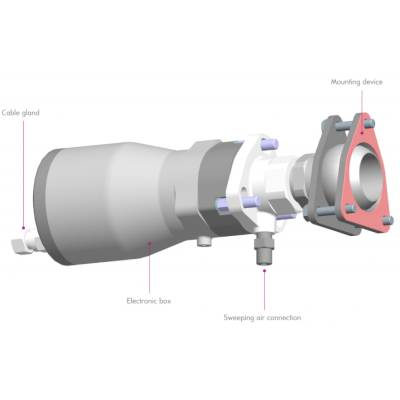

Pillard flame scanners – Real time flame monitoring compatible with all fuels

Fives’ complete range of flame scanners ensures a secured combustion process thanks to state-of-the-art detection technologies. Pillard flame scanners are adapted to different types of fuels and combustion processes.

EASY INSTALLATION

− “All-in-one” design includes electronics control integrated within the flame scanner sight

− No remote box, nor cable needed

APPLICATIONS / MARKETS (non-exhaustive list)

Pillard flame scanners are compatible with all type of fuels and can be used in the following industries:

− Energy

− Petrochemical

− Cement

− Chemical

− Steel

− Claus unit

EASY OPERATION AND MAINTENANCE

− Innovative IR remote control

− Flame level display directly on the detector

SAFE EQUIPMENT

Pillard flame scanners meet the most stringent safety regulations and compliance:

− ATEX / IECEx (EN 60079)

− SIL3 (EN 61508)

− TUV (EN 298)

− FM approvals

PROVEN AND FLEXIBLE TECHNOLOGY

− Can be used in hazardous combustion areas

− Adapted to all customer requests whatever the power and sites constraints

Neo Monitors

High Performance Dust and Gas Analyzers based on TDLAS

NEO Monitors AS was founded in 2003 as a commercial part of Norsk Elektro Optikk AS (NEO). Today, NEO Monitors is a leading manufacturer and supplier of Tuneable Diode Laser Absorption Spectroscopy (TDLAS) gas and dust analyzers, based on over 30 years of high-risk research and development in electro-optics and laser technology.

NEO Monitors AS was acquired by the Nederman Group in 2017. Our Dust and Gas Analyzers are the preferred choice for a broad range of applications within process and emission control. Our products are sold through a global network of distributors.

Our quality management system is ISO 9001:2015-certified

NEO Monitors LaserGasTMII Open Path (OP) Monitor is s a compact, high performance gas analyzer for long distance monitoring in ambient air. Measurement lengths of up to 1000 m. The OP Monitor utilizes a transmitter / reflector configuration to measure the average gas concentration along the optical line-of-sight. As option a self-contained, battery-powered version is available with a control keypad and a flash memory for data logging.

The monitor is installed on our proprietary x/y alignment platform (goniometer). Adapters for fixed installation on platforms or for tripod use are available. The instrument also includes a visible aiming laser and sighting optics for easy alignment even over long distances. Hoods for protection of the optical windows on transceiver and reflector side can be supplied.

Product application:

C2H2, C2H4, C3H6, CH4, CO, CO2, H2O, H2S, HCL, HCN, HF,N2O, NH3, NO, NO2, O2, VCM

TDLS Analyzer

The first all-in-one TDLS analyzer is a complete gamechanger.

NEO Monitors’ LaserGasTM iQ2 analyzer is the first to measure four gases (O2, CO, CH4, H2O) and temperature in one unit, which liminates the need for multiple units for combustion analysis. The cutting-edge design and ground-breaking functionality, ensures that the instrument delivers unmatched reliability and durability.

LaserGasTM iQ2 is developed on a well proven technology platform. With innovative design and extraordinary spectroscopically and optical solutions, the customer gets an accurate and reliable analyzer solving application needs such as FCC units, package boilers, process heaters, electrostatic precipitators, VCM waste gas recovery, reformer gas, incinerator and so forth.

By providing an optional single flange or cross stack configuration, installation cost can be significantly reduced. Customers may replace existing analyzers where explosion risks or high maintenance issues are a huge concern.

RJM International

Emissions Reduction Technology for Coal, Oil, Gas and Biomass Fired Plants

RJM International is a specialist, award-winning provider of a range of innovative and technologically-sophisticated products and services aimed at supporting the power and industrial plant sectors.

Working with some of the world’s leading utility supply companies and owners of other large combustion plant, RJM helps them to operate as efficiently and as cost-effectively as possible, whilst also enabling them to meet the latest emissions regulations governing SOx, NOx, particulates and carbon.

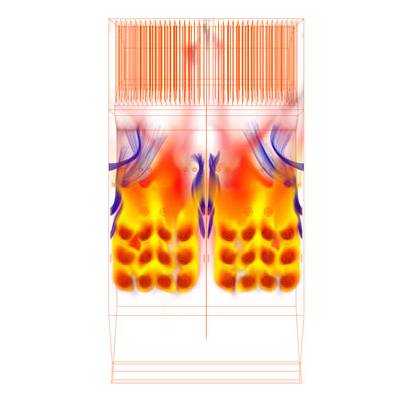

Ultra-Low NOx coal burners

RJM has a strong global track record in delivering emissions reduction technologies and products to enable coal-fired plants to consistently and reliably meet increasingly stringent emissions targets, whilst firing globally-sourced fuels. At a recent project at SSE Ferrybridge, RJM’s Ultra-Low NOx burners brought NOx emissions down to 250 Mg/Nm3.

Ultra-Low NOx oil burners

RJM has also optimised a range of Ultra-Low NOx oil burners that perform reliably and meet the latest emissions regulations. Much of the detailed testing and refining took place on the International Flame Research Federation test rig at its laboratory in Pisa. Today, RJM Ultra-Low NOx oil burners are fitted to power stations all over the world, including AES Kilroot in Northern Ireland.

Ultra-Low NOx gas burners

RJM has installed its Ultra-Low NOx gas burners at power stations across the USA and in Europe enabling them to become NOx compliant. At Essent’s Clauscentrale power station in the Netherlands, RJM brought NOx levels down from 400 Mg/Nm3 to below 100mg/Nm3. Read the full article here.

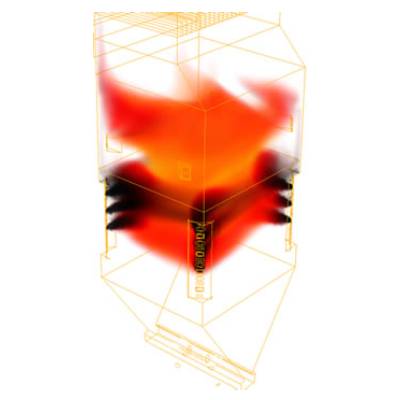

Ultra-Low NOx biomass burners

RJM has proven its ultra-low NOx biomass burner design on the burner test facilities of a major generator and has been developing its own CFD code to replicate more precisely the combustion characteristics of biomass matter. The findings from RJM’s own CFD-based research, combined with the lastest physics available, are now being applied to fine-tune RJM’s biomass burner design for co-firing and full biomass conversion applications. RJM’s range of biomass-configured burners are now available to order.

Overfire air (OFA) systems or boosted overfire air systems (BOFA) are a common feature on many of today’s fossil-fuelled power stations. Often they were introduced to meet a new level of NOx reduction compliance that could not be achieved through burner modifications alone. In addition, OFA or BOFA provided a low NOx solution that meant the installation of costly selective catalytic reduction (SCR) systems or selective non-catalytic reduction (SNCR) systems to achieve the same result could be avoided.

RJM has considerable experience in installing new OFA and BOFA systems and can deliver incremental NOx reductions of up to 40%, through the implementation of multiple OFA ports, using either forced draft fan pressure air or boosted air delivery systems. RJM’s recent experience in this field is based on fine-tuning existing OFA / BOFA systems, in conjunction with either existing low NOx burners or with new RJM Ultra-Low NOx burners. RJM’s recent NOx reduction programme at SSE Ferrybridge is a good example of how critical it was to get the BOFA system operating effectively to ensure the plant could a) meet its new low NOx targets as set out by the Large Comubustion Plant Directive and b) run efficiently with correct boiler and burner dynamics. Read full article here.

Conversely, at another plant in Eastern Europe, following an engineering study that showed its existing OFA systems were in fact not well-suited for the boiler and burning configuration, RJM recommended that the OFA system be removed and that a different technology for NOx control be adopted. Once this had been carried out, the plant reached its emissions targets immediately.

For new OFA or BOFA installations, RJM will design a system to best suit the project objectives. CFD analysis will ensure a properly designed OFA system prior to installation. RJM’s OFA systems are individually designed to suit any make of boiler and combustion system.

RJM’s solution will always endeavour to minimise cost but maximise NOx reduction, whilst maintaining zero or limited impact on carbon carryover and boiler efficiency. The final configuration will be dependent on many factors, including OFA jet penetration to ensure burnout of combustibles, the physical space available around the boiler, access to the OFA locations, the fan and windbox air pressures available, constraints on furnace CO concentrations and excess oxygen limitations.

Using our bespoke CFD modelling service together with our highly experienced team of combustion specialists, RJM is able to design, manufacture and install new OFA and BOFA systems or modify and optimise existing systems and has a number of satisfied clients and reference sites where this has been done.

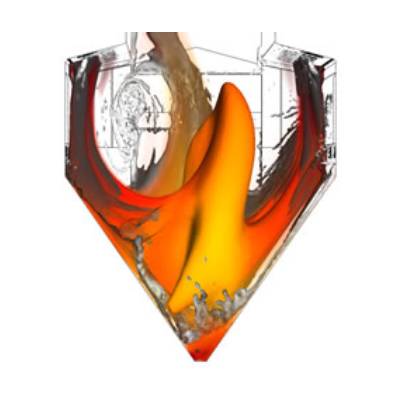

CFD modelling (Computational Fluid Dynamics) is one of the main methodologies used by RJM to accurately measure and define the combustion process dynamics which take place within coal, oil, gas and biomass-fired boilers and furnaces.

CFD modelling is typically used in conjunction with a physical site survey to provide actual plant performance, so that a baseline model can be established within the CFD model that replicates existing unit performance as its starting point. The site survey also serves to verify baseline process data including NOx, CO, excess oxygen conditions as well as furnace exit gas temperatures and other key parameters.

Once the baseline conditions have been established and confirmed as representative of the field data, RJM will run the CFD model to analyse every aspect of the combustion process and to identify what combination of changes, modifications or upgrades might be applicable to deliver the emissions reductions or efficiency improvements required by the plant operators. This is complex and detailed work and RJM continues to invest heavily in refining and developing its own CFD modelling software to ensure greater accuracy and to be able to offer its customers a more detailed analysis of the combustion challenges and a more rigorous set of solutions to address them.

Typically, the difference between the baseline emissions and performance, compared to the proposed modifications to operating procedures and plant upgrades proposed by RJM, determines the performance improvements and emissions reductions that can be achieved. RJM follows a strict and logical iterative procedure until the upgrade performance falls in line with the project objectives. Once this is achieved, RJM will design, manufacture and install any new components that are required, make modifications to existing equipment and work with plant operators to ensure that new operating procedures deliver the results required.

As RJM’s CFD modelling is so sophisticated, it enables all modifications to the combustion process to be tested for effectiveness off-line, before any physical hardware is fabricated. In this way, CFD modelling accelerates the design process, as it provides fast and reliable results. It is also used as a tool to shorten downtime, as settings for commissioning can be estimated before the equipment is installed. This often results in major cost savings to our clients.

CFD models are complex programmes and require substantial experience and expertise to give reliable results. RJM uses CFD modelling on all emission reduction projects and in fact, RJM was the first company to modify other manufacturers’ burners to change them into low NOx performers.

Our reference list speaks for itself. With over 60,000MWe of installations to our name, encompassing all makes of burner and boiler, with all types of firing configurations deploying every commonly-fired fuel, RJM’s modelling capability and historical success is second to none. More.

Scentroid

Air Quality and Odour Monitoring Instruments

Scentroid is the world’s leading manufacturer of Air Quality and Odour Monitoring equipment. Based in Toronto, Canada, we ship to over 45 countries around the world. Our clients include government agencies, environmental laboratories, research institutions, and various industries who want nothing but the best air quality possible.

AQmini

Ideal for Multiple Industries

The AQmini Compact Indoor Air Quality Monitor is both a versatile and cost-effective solution for all your indoor air quality needs, eg manufacturing facilities, airports, healthcare facilities etc.

CTmini

Particulate Matter Monitor

Delivers highly accurate data on PM 1, 2.5, 4, and 10, Temperature and Relative Humidity. With quick installation, compact design, battery options, and seamless cloud connectivity.

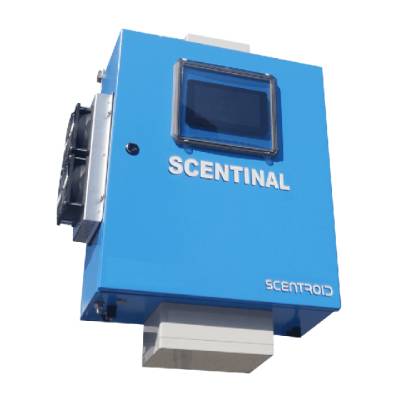

The Scentinal SL-50 ambient air quality analyzer (AQMS) continuous monitoring station provides high accuracy (ppb level) detection of odorous gases such as H2S, NH3, VOCs, SO2 & odour concentration. The intelligent sensor network allows live monitoring of plant odour emissions on Scentroid’s cloud servers. The innovative design of Scentinal offers a reliable and cost effective odour monitoring solution.

The central monitoring station is hosted on a secure cloud based server allowing remote access via any computer with internet access. This access is restricted and the data is encrypted for maximum security. Users are given a password and user name which will define their permission level.

The CTair+ air quality analyzer continuous monitoring station is a fixed urban-based unit that collects information and presents the data in an easy to understand graphical interface. It has been designed to be dispatched into a network of units. Due to its lightweight build (10 lbs) the CTair+ unit can easily be installed and mounted to a light fixture or utility pole.

The CTair+ Urban Air Quality Monitor is a fixed unit that collects information on the air quality by city and presents the collected data in an easy to understand graphical interface. It has been designed to be dispatched into a wider network of CTair+ units. Due to its lightweight design at 10 lbs, the CTair+ unit can easily be installed and mounted to a light fixture or utility pole. By applying information collected from multiple data points, the CTair+ allows the user to gain a complete understanding of the chemical compounds being monitored.

The Urban Scanner™ is a complete platform that provides detailed air quality information within urban landscapes. It achieves this by collecting and combing a variety of information such as air pollution concentrations, a 3D map of the city, traffic conditions, micro-weather patterns, and more. Data is collected using a weather-proof, easily mountable device.

Handheld Air Quality Chemical Analyzer

The TR8 Odotracker Handheld Analyzer is a multi-sensor analysis tool that measures the concentrations of two chemicals in ambient air at the same time. Chemicals to be measured by the device are specified at the time of ordering. As a result, the user may specify the measurement of Hydrogen Sulphide (H2S) at ppb-level and Ammonia (NH3) at ppm-level. The TR8 Odotracker is an incredibly helpful tool, because it logs the chemical measurements as well as temperature and humidity of the sample, GPS location, and automatically transfers all data to the user’s supplied smart Android device via Bluetooth.

A TR8 Odotracker Handheld Analyzer Includes a sampling pump, two chemical sensors that are specified at the time of ordering, and Scentroid’s OdoTracker Application that can be loaded to any customer supplied Android phone/tablet. For each sample location, Scentroid instantaneously records:

- Concentration of two chemical vapours in ppm or ppb depending on sensors ordered

- Temperature and humidity

- GPS position of each measurement

Continuously for remote monitoring via Bluetooth

The Scentroid TR8 Plus Pollutracker is a complete air quality monitor and mobile laboratory. Users can measure ambient air quality & greenhouse gases due to it using up to 10 sensors and analyzers including photo-ionization detectors (PID) sensors, non-dispersive Infrared (NDIR) sensors, electrochemical, and metal oxide sensors. Each Pollutracker includes a built-in 10″ touchscreen interface, on-device data logging, wireless transfer via email, remote (internet-based) firmware updates, built-in sampling pump, simultaneous data analysis of gases, built-in rechargeable battery, and an on-screen calibration procedure.

Also Includes a sampling pump and Scentroid’s Pollutracker tracker application that can be loaded to any customer supplied Android phone/tablet. Two chemical sensors can be specified at the time of ordering. For each sample location, Scentroid instantaneously records:

- Concentration of two chemical vapours in ppm or ppb depending on sensors ordered

- Temperature and humidity

- GPS position of each measurement

- Continuously for remote monitoring via Bluetooth

TCR Tecora

Industrial Emissions Monitoring Instruments

TCR Tecora is a leading supplier of stack emissions sampling systems, continuous dioxin emission samplers, gravimetric samplers, industrial hygiene devices, oxygen and combustion control analyzers. Our mission is to design products compliant to international standards, helping environmental engineers and stack testers to improve its productivity and minimise off-spec products in industrial processes.

Bravo DUO is a constant flow sampler with 2 diaphragm pumps and double heads!

The heart of BRAVO DUO consists of two diaphragm pumps resistant to aggressive gases. Flow control is assured by a microprocessor board.

Two independent samplers in the same chassis! This means:

- To carry out double sampling with different methods;

- Less weight during transport;

- Less amount of space required during access to the sampling area.

An external colored LED stripe, visible from a long distance, indicate the running condition during sampling (ok, warning, alarm, stopped).

Isostack G4 is the 4th generation isokinetic sampler of TCR Tecora

It is the result of a long tradition of isokinetic sampler, started in 80s with Isostack B6.

The solution offered with this new instrument can be summarized in 4 main characteristics:

Easy to use

Isostack G4 offers two different configurations to meet different type of use.

It is available in a “all in one” and in a “split” version.

The first is dedicated to whom wish to reduce the costs and have the maximum portability.

The second to whom wish to carry on stack platform only the control panel and leave on plant floor the pump unit

Reability

Isostack G4 uses quality components which grant reliability in time.

Last generation electronics, which assures high immunity from electromagnetic noisy and designed to work even in severe ambient conditions .

Accuracy

High precision pressure sensor with thermal drift compensation.

Thermocouple calibration curve following ITS 90 standard.

Sampling Quality (QA/QC)

Calibration curve on 5 points for each sensor and acquired width. Correction curve on 5 points programmable by customer for each sensor.

Allows adjusting deviations eventually found during re-calibration.

Volume measurement redundancy now coming from a mass and a volume meter.

ECHO PM is a “stand alone” instrument projected for outdoor operation in harsh climatic conditions. The wide regulation range and the accurate electronic flow sampling control at either actual or standard conditions, makes ECHO PM in accordance with the reference methods EN 12341 for PM 10 with head LVS PM10 2.3 m3/h, and US EPA 40 CFR pa rt 50 for PM10 and PM2.5 at 1m3/h

Autonomous sampling with maximum 2 sequential samples* .· Electronically controlled flow rate sampling at standard and actual conditions· Wide graphical display with background illumination, dedicated keyboard, RS232 inter face· Permanent date and hour programming· Sampling time with 1″ resolution is selectable from 1′ to 168 h

Bravo Basic

Constant Flow Sampler

Bravo X

Constant Flow Sampler

DDS

Portable Dynamic Dilution Sampler for

DECS

Dioxins Sampling on Stack

Echo Hi-Vol

Micropollutants High Volume Sampler

FlowCal Air

Simple Flow Calibrator

Flowtest ST

Stack Gas Velocity and Flow Meter

Peltier EG

Cooling System

UniTec

Ambient Continuous Analyzer

UniTec was founded in year 2000 to design, develop and manufacture innovative instruments in the field of air quality monitoring. With their experience in the market of air quality and water continuous monitoring systems, they provide Consulting, Design and Support Services to our customers.

The ETL3000 is a multi-component air quality monitor for measuring airborne pollutants in parts per billion (ppb) concentrations. The system is based on a new solid-state thick-film sensor technology, which provides excellent sensitivity and accuracy. The performance of the sensors is superior to conventional electrochemical cells. The monitor provides measurement of CO, NO2 and O3. In addition temperature, humidity and noise is simultaneously measured. The system has a built-in data logger and a GSM modem (optional). Analysis of C6H6 and other parameters with thick film sensor is also available as an option.

The ETL3000 is designed specifically for outdoor installation. A mounting kit is supplied, suitable for any pole diameter. The electronic part is now based on a microprocessor with flash memory and it is completely separated by the sensors. Each sensor is independent and is installed inside its cell (SENS3000) and connected to the electronic with plug-play connectors. The sensors can be replaced easily in the field.

Our innovative application of Mobile Monitoring of Traffic Pollution in cities can be done by installing the ETLBUS system on public transport vehicles and positioning using GPS. It is possible to develop special custom applications of ETLBUS and software with GIS system to handle also instantaneous data positioned on the local map.